|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Name: Kevin Luo |

disposable baking paper cake tray forming machine(BJ-CTA) |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

| Product name : disposable baking paper cake tray forming machine(BJ-CTA) | ||||||||||||||||||||||||||||||

| Item : cake tray machine | ||||||||||||||||||||||||||||||

| Details : | ||||||||||||||||||||||||||||||

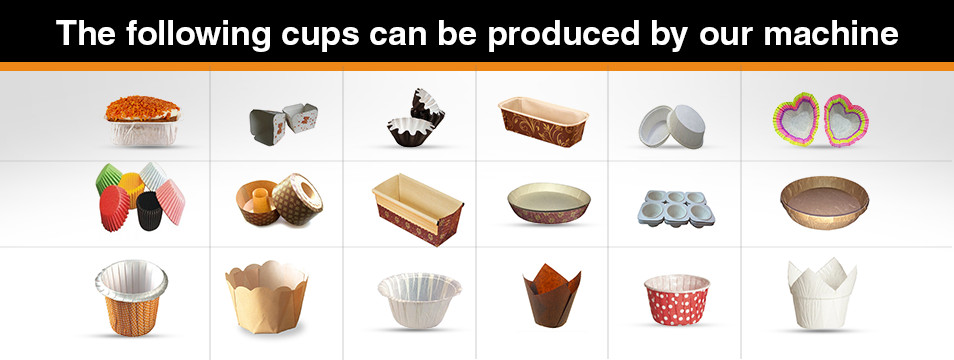

Model BJ-CTA Automatic Paper Cake Tray Forming Machine is made after the Italian technological innovation assimilation apparatus which has a simple structure, easy to operate, fast and reliable production efficiency advantage at home and abroad, first-class equipment performance. The technology of cake tray machine is adopt from Italy, which is one of our most hot sale products.It can greatly save your labor cost as it is with the functions of automatic feed paper and collect the end products, so the semi-automatic baking cup machine is replaced. Our machine can be used with many different types of cake tray machine mold. Cake tray making machine has advanced technology, such as pneumatic manipulator, paper collection control, automatic paper, molding and heat, trays and other discharge Easy replacement of the mold, so that the different size carton and foil tray. It is an ideal paper cake trays, paper food trays, paper cake cups, paper food dishes, cake pans, cutlery and containers of cake. Advantages:There are more that 20 factories for automatic cake tray machine in China. We can not guarantee you the mostlowest price, but we can promise you the unique product quality.

Cake tray making machine a ideal equipment of making paper cake trays, paper food trays,

paper cake cups, paper food dishes, cake plates, cake dishes and containers etc.

Our service:

1. 1 year warranty 2. Guidebook machine to guide the installation process engineering, machine adjustment, production, avoide or settlement, the buyer will face problems. 3. We will adjust the machine as well as a week before delivery, to ensure that the machine has a perfect performance. 4. We can send a technician to the buyer's factory, installation guide, a period of adjustment, salaries, travel expenses, accommodation, communication and daily living expenses 100USD buyer incharge. 5. We offer buyers free training, training will not stop until the buyer control over the entire leson! Tickets should be provided by the buyer, room and board costs. 6. We offer one year free use of consumable spare parts. |

||||||||||||||||||||||||||||||

|

вҶҗ[Previous : 2016517123433] [Next : 201642010919]вҶ’ | |||||||||||||||||||||||||||||

| Related Products : |

Muffin Cup Machine

Muffin Cup Machine