|

|

|

Name: Kevin Luo |

Shrink |

| Author : Date : 2014-4-12 23:52:13 |

baking cup machine After heat shrinkable plastic film by Canadian packaged food , close to the food surface , can slice or loose food crunch as a whole , easy to transport and sales. Shrink packaging uses a wide range of small to retail packaged foods , ranging from the entire pallet of goods .

Shrink packaging material is used in the cooling process after stretching and orientation of the plastic film. Since the film residual shrinkage stress generated in the orientation stretch when subjected to hot air or infrared light irradiation process , the film area is reduced , increasing the thickness , and thus close to the packaged food , and to maintain this long contraction . Shrink packaging can be divided into three programs. в‘ wrapped and sealed : The film has been stretched and heat sealing the food parcels . Parcel and equipment used according to the product type and size. в‘Ў heating: the contraction of the film , to be heated in the shortest time to not less than 110 в„ѓ. The main heating convection heating , infrared radiation and infrared indirect direct radiation . Heating process is generally carried out in the tunnel , then the film absorbs heat, crystallization becomes amorphous state , but has not yet played contraction. в‘ў Cooling: When the temperature drops below 110 в„ѓ, the crystallization of amorphous films again , resulting in contraction , when the film area is reduced , the completion of shrink packaging process. |

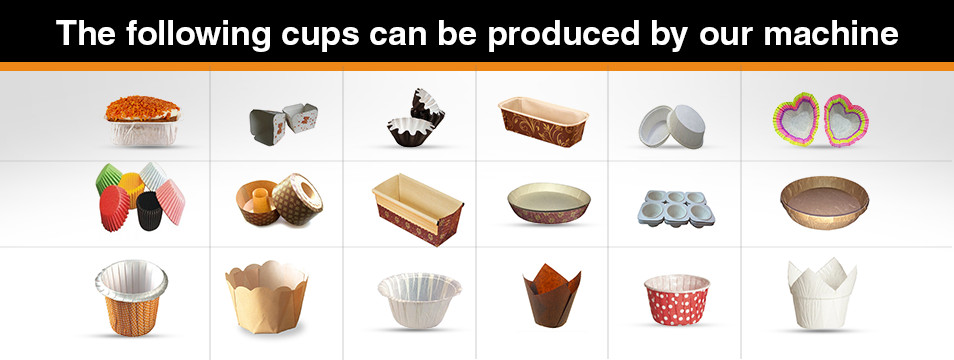

Muffin Cup Machine

Muffin Cup Machine